By recognizing hazards, using personal protective wear and following established safety rules and procedures, you can save your hands from injury and yourself from an unnecessary disability. The most common causes of hand injuries are Carelessness, Lack of awareness, Boredom, Disregard for safety procedures & Distractions

There are times when it can be unsafe to wear gloves, such as when working with machinery with exposed moving parts. However, there are many activities where using a proper glove will prevent an injury or at least minimize the severity of the injury. Rough or sharp edges, burrs, protruding bolts, metal with sharp edges, glass and wood splinters can all cause minor to severe lacerations and punctures without the use of gloves.

Prior to handling chemicals or hot and cold material it is necessary to use gloves. Take the time to find the right tool for the job. In addition to using the right tool, keep tools and equipment in good repair and maintain sharp cutting blades. Periodically inspect tools for cracks, wear, and proper function. Dull utility knives or saw blades take more effort and force to cut the material. This can only spell trouble if there is a slip.

When working with machinery, make sure all guards are in place and properly adjusted. Never remove or circumvent guards and controls as they are designed to protect you from coming in contact with potentially dangerous moving parts. These controls as well, should be used as designed and not bypassed in order to speed up work. Make sure that the work place is properly illuminated, especially near the machines to be used. Improper and inadequate illumination is one of the major reasons for industrial trauma. There are times when due to the force, frequency, hand position and static grip, hand strains are caused. Avoid such strains by considering the following:

In spite of the adequate care taken while working, accidents do occur.

Incase a hand of a worker is crushed in a machine,

Switch off the main current, open up the machine and then remove the hand out of the machine. Do not run the machine in the reverse direction so as to remove the entangled extremity. This will cause additional trauma to the already compromised hand.

After the hand is removed out of the machine, apply a tight dressing to it using the first aid kit to control the bleeding. In case the bleeding doesn’t stop apply a tight bandage or cloth at the arm level to act as a tourniquet, and shift the patient as fast as possible to a hospital. Do not apply grease, tobacco, tar or any other like substances to the wound. If possible irrigate the wound with plenty of tap water to remove the gross contamination present in the wound.

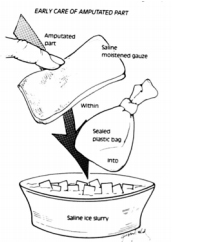

In an unfortunate event of amputation of the hand or fingers, the amputed part must be cleaned with saline or tap water, must be wrapped in a moist cloth, and kept in a water tight plastic container. This plastic container in turn must be kept on ice. The patient and amputed part must be shifted as soon as possible to the nearest tertiary care centre. Do not keep the amputed part in direct contact with the ice as this will cause damage to the amputed part because of freezing. Do not keep the amputed part dipped in water or saline as this will lead to the maceration of the tissue of the amputed part.

Prevention is always better than cure. So be alert, be careful and prevent Hand injuries. Save Hands. A hand saved is a family saved.